Hoping for a rebound early next year, many suppliers offer solutions for manufacturing and retail partners that are seeking efficiencies and ways to cut costs

HICKORY, N.C. — Industry equipment, materials and service providers showing at this past week’s Furniture Manufacturing Expo had a chance to connect with furniture manufacturers hoping for a turnaround if not in the second half, sometime early next year.

Held June 13-14 at the Hickory Metro Convention Center, it featured nearly 100 exhibitors offering equipment ranging from sewing machines to large-scale fabric and leather cutting machines plus materials such as hardware, plywood panels, brackets, nailhead trim, dowels, webbing, adhesives and more for manufacturers and distributors. Many came to visit with existing resources, and many came to meet new resources to help diversify their mix of suppliers.

“With what happened to the supply chain during Covid, I would hope that everyone sees the benefit of having multiple suppliers,” said Mark Hill, a trader with lumber and engineered wood particleboard supplier Richmond International.

With customers in the upholstery and case goods segments as well as wood cabinetry, he noted that the company has shown at the expo for several years. This time around, it saw new customers and prospects from North Carolina, Maryland, New Jersey and Ohio and as far west as California.

“This is one of the best shows we do every year because it attracts a lot of decision makers,” he said, noting that the company has warehouses around the country that serve customers in those regions, many of whom buy product in truckloads.

For Richmond and other suppliers, a key purpose of the event is to help educate customers about the services and products available, as opposed to actually selling product. Those buying decisions, more often than not, take place between shows where companies can review their options, similar to large retailers attending a furniture market.

“Right now, the market is flat and it’s not as hard to find stuff,” Hill added, noting that it’s still important for the industry to know what’s available in the marketplace.

Leggett & Platt, for example, showcased new mechanisms for recliners and sleepers, allowing customers to see some of its various innovations in person, including a recliner that converts into a glider rocker. As importantly, it gave the company and its customers a chance to reconnect in a casual and informal setting.

“It’s just an opportunity for us to engage with our customer base,” said Taylor Knuckles, a company sales professional who covers North Carolina and the Northeast. In addition to some customers from up north, he said the show mostly drew existing customers and some prospects from the North Carolina region as well as Georgia and Tennessee. He agreed that this also is an efficient way for suppliers and their customers to meet in one setting.

“People are wearing multiple hats, so time is of the essence,” he said, adding, that the face-to-face meetings give companies a chance to interact on a personal level. “Everyone’s asking the same question — ‘How’s business?’ 98 to 100% of the suppliers here would give you the same answer — ‘it’s soft right now.’”

For that reason, the company and others are offering new products and solutions aimed at spurring manufacturing efficiencies and/or interest among consumers.

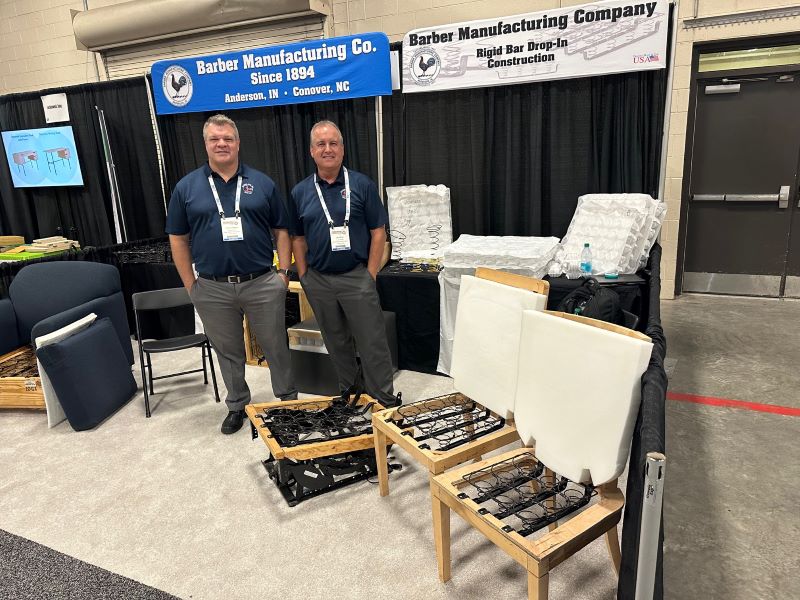

Seat spring manufacturer Barber Manufacturing, for example, showed some of its innovations in the segment, including rigid bar, drop- in construction that features single-cone springs attached to roll-formed steel channel bars. Together, they form a rigid bar drop in for a recliner, that provides more comfort than sinuous spring construction.

A similar type of construction also was available to drop into the frame of a dining chair. (This writer tested it out as he hadn’t seen anything like it in the market previously. The fact that he did the entire interview seated in the chair — without wanting to get up — was one indication this could be a hit at retail.)

“It is more expensive than sinuous (spring support), but we have some customers for it,” noted Jan Miller, general manager, adding that sinuous spring support also has been the norm in recliners.

However, this could be a game changer as the coils provide comfort across the entire seat regardless of the position of the recliner. By comparison, the sinuous springs provide more give in the middle, but are typically more rigid along the front and back of the seat.

Associated Hardwoods was on hand to help educate customers about how it can tailor the specs of wood frames and plywood to the needs of the customer, thus allowing them to do as much or as little of the wood processing as they want in house.

“Even with it being slow, it’s still a challenge,” said sales associate Jay Osmer regarding labor and getting workers with the right skill sets.

Thus, lumber yield remains a critical element, particularly for furniture manufacturers looking to maximize efficiency and also cut down on material costs.

“The furniture industry is dependent on yield,” Osmer said. “Yield is money.”

The company visited with customers — some from as far away as Texas, with others stopping by from North Carolina, Virginia and Tennessee — to help communicate the services and technologies the company can provide not just during a slow economy but also when business improves.

Hickory Springs was on hand to help educate customers — existing and new prospects including upholstery and bedding manufacturers from the Carolinas plus Michigan, Indiana, Tennessee and Massachusetts, to name several — about its many products and services. Part of the education process also was on how some of these products also can help customers improve efficiencies, while also maximizing the comfort level and durability of their products ranging from sofas to mattresses.

Conversations also focused on the state of the economy, noted Jason Porter, vice president of sales for the furniture segment.

“We are asking them and they are asking us, how they are seeing things and how we are seeing things,” he said, adding, “People are optimistic that we will come out of this. The key is timing. We are preparing for what’s coming.”

Miller, of Barber Manufacturing Co., said the company saw both existing customers and new prospects. Here, too, conversations also touched on the economy, with hopes of a turnaround sooner than later.

“It’s feast or famine for a lot of people,” Miller said, adding that middle to upper end is generally not having as hard a time as the lower middle to lower end of the spectrum. Some companies, he noted, are maintaining their workweek, while others are working three- to four-day weeks, with others still working overtime. “But not many,” he said.

Some also noted that in typical election-year fashion, many are waiting to pull the trigger on spending until after Nov. 5. Lower interest rates, they note, also will have a major impact on home buying and selling, which typically spurs furniture sales.

“Business has been way off for close to a year now,” said Mark Miller, a senior account manager at Beeson, which supplies the industry products ranging from plywood and sandpaper to screws, glue and safety supplies. “Furniture is driven by the overall economy, and consumers are not spending money. And furniture factories are not spending money they don’t have to spend and are very frugal on what they do spend. Everybody is waiting for and hoping for a change in November. You cannot keep going down the path we have been going. … People have been tightening their belts and trying to run smarter and more efficient, and you can only do that for so long.”

He said this was the company’s first year at the show and that he was pleasantly surprised at the depth and breadth of attendance from states as far west as California, Utah and Texas, not to mention Oklahoma, Illinois and Massachusetts.

“I thought this would be a more regional show, and it’s been much broader than that,” he said, noting that this will help with new business prospects.

“We are looking at expanding our customer base,” he said, adding, “Our current customers are very loyal and are giving us everything they can. We are just looking for new customers to broaden our scope.”